Additive Manufacturing (3d Printing)

Our service:

To help our customers with rapid prototyping or fabrication via 3d printing method. With just a 3d drawing, we could help our customers to instantly print a working prototype or concept modelling and validation. With the ability to reinforce parts with materials such as carbon fibre, fibreglass, Kevlar, the part can withstand enormous stress from repeated use or impact.

Our in-house design capability include CAD software such as Autodesk Inventor, Solidworks and Solid Edge, with more than 20 years combined experience in designing and 3d drawing, be rest assured that we’re up to any challenge.

Our facility:

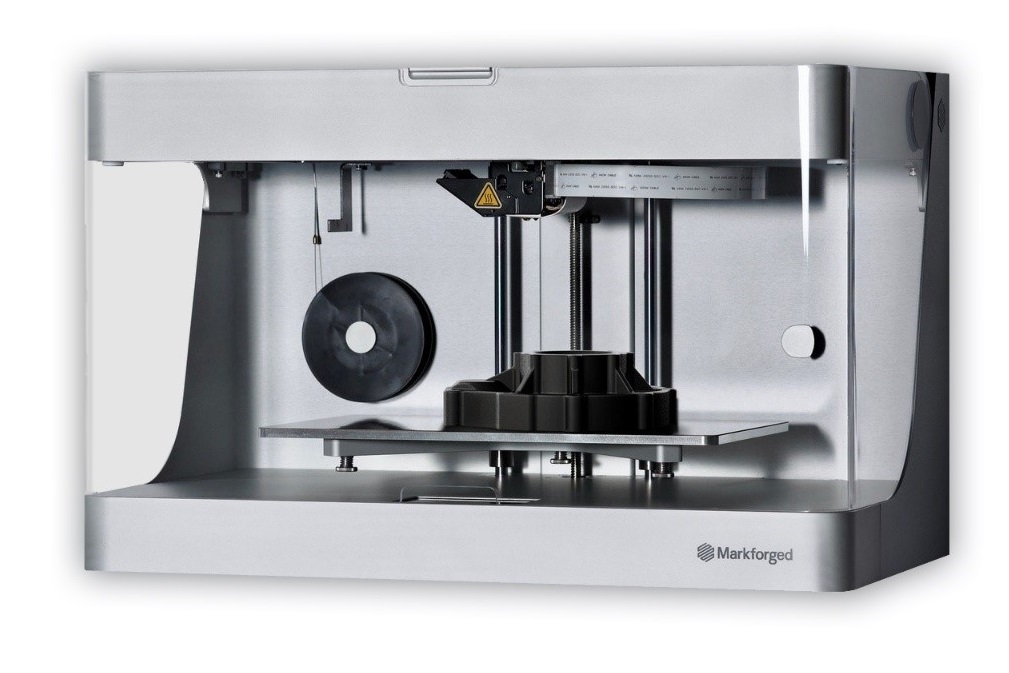

Markforged Mark 2 Continuous Fiber Composite 3d printer.

Able to make aluminium-strength parts, reinforced with either Carbon Fibre, Fibreglass, Aramid Fibre (Kevlar) or HSHT (High Strength High Temperature) Fibreglass.

Materials:

Onyx™ is a micro carbon fiber filled nylon that yields accurate parts with near flawless surface finish. Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts.

Carbon Fiber is Markforged’s unique, ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers.

Fiberglass is Markforged’s entry-level Continuous Fiber —a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx.

Aramid Fiber is a Kevlar® based, specialized Continuous Fiber known for its energy absorption and extreme toughness. When laid into Onyx or another Composite Base material, it yields impact-resistant parts that are nearly immune to catastrophic failure (fracture). It’s perfect for use in parts that are in demanding environments or are subject to repetitive loading.

High Strength High Temperature (HSHT) Fiberglass is defined by two characteristics: high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures. Though not as stiff as Continuous Carbon Fiber, Onyx parts reinforced with HSHT are strong at both low and high temperatures. As a result, HSHT reinforcement is best used for parts in high-temperature environments like molds, autoclaves, and others.

Size (build volume):

Width – 320mm

Depth – 132mm

Height – 154mm

Print Sample: